Artillery Sidewinder X4 Plus: In-Depth & Hands-On Review

Share

The Artillery Sidewinder X4 Plus* marks the latest addition to the Artillery 3D printer family. This hands-on review aims to evaluate the printer from a real-world perspective, with a particular focus on technical specifications, ease of use and performance in everyday use.

We examine how the Sidewinder X4 Plus stands out from other models with advanced features such as input shaping, automatic print bed leveling and high-temperature filament support. The aim is to give you a clear idea of how this 3D printer performs in different usage scenarios.

My Verdict – What Sets the Artillery Sidewinder X4 Plus Apart?

The Artillery Sidewinder X4 Plus builds on the success of its predecessors and integrates modern features that make it an attractive option for a broad user base.

Input shaping and automatic print bed leveling significantly increase precision and ease of use, while high-temperature support enables a wide range of materials. The touchscreen and high print speeds further simplify operation. The large print volume allows larger objects to be printed in a single pass.

Despite the lack of revolutionary innovations, the X4 Plus impresses with its high quality and reliability, which also makes it attractive for beginners. Its strengths therefore do not lie in ground-breaking innovations, but in the solid implementation of proven technologies and the reliable performance it offers.

Unboxing & First Impression

When unpacking the Artillery Sidewinder X4 Plus, it is immediately apparent that the 3D printer is delivered partially pre-assembled. Each module is carefully packed to prevent damage during transportation.

The linear rails stand out as a modern solution for high printing speeds, a trend made necessary by features such as input shaping. The ever-increasing printing speeds make such stable axis rails necessary to prevent printing errors caused by unstable movement.

The build quality is consistently high, a feature that is to be expected from Artillery models. In addition to the printer itself, the scope of delivery includes everything necessary for assembly, useful accessories such as spatulas, side cutters, a needle for nozzle cleaning, spare parts, grease for the linear rails, instructions, a USB stick with software and test files.

A glue stick is also included, although the print bed offers excellent adhesion and actually makes it superfluous.

Assembly

Assembly of the Artillery Sidewinder X4 Plus is simple due to its partially pre-assembled state and takes little more than 15 minutes.

First, the frame with the pre-assembled print head is attached to the base. Then the filament holder with sensor is installed on the top frame and the display is mounted on the side. The WiFi antenna is screwed in and all cables are connected accordingly. Finally, the cross struts are mounted to stabilize the frame and the printer is ready for its first use.

Print Bed & Leveling

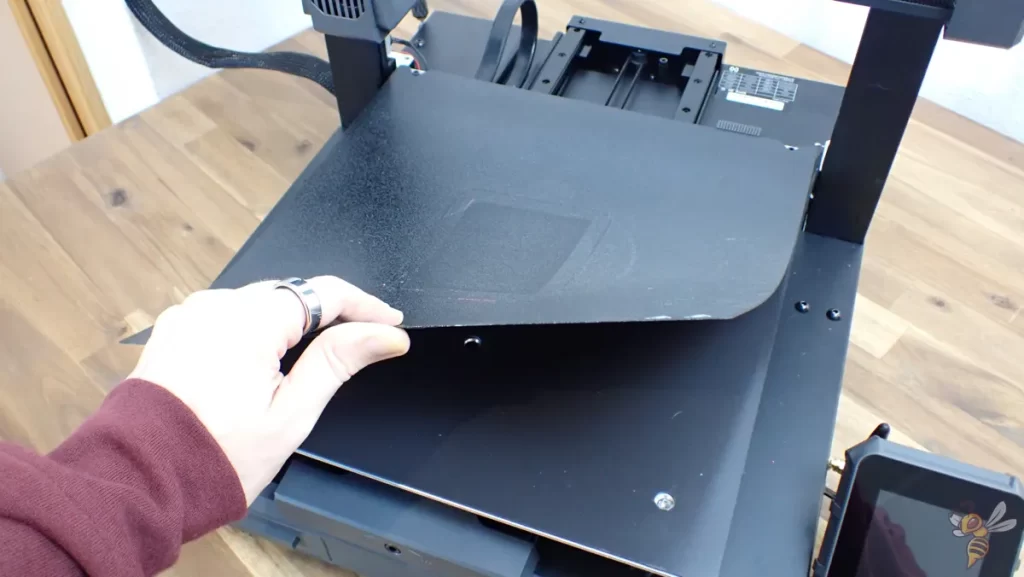

The print bed of the Artillery Sidewinder X4 Plus has a rough PEI coating, which stands out from the smoother surfaces of many modern 3D printers. This coating provides excellent adhesion, sometimes even too good, which can make it difficult to remove the prints.

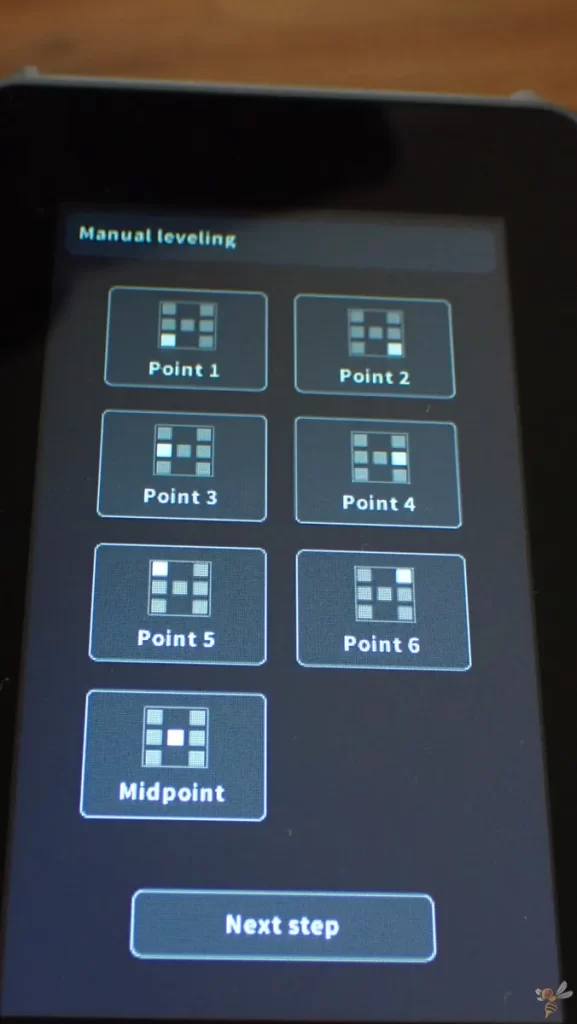

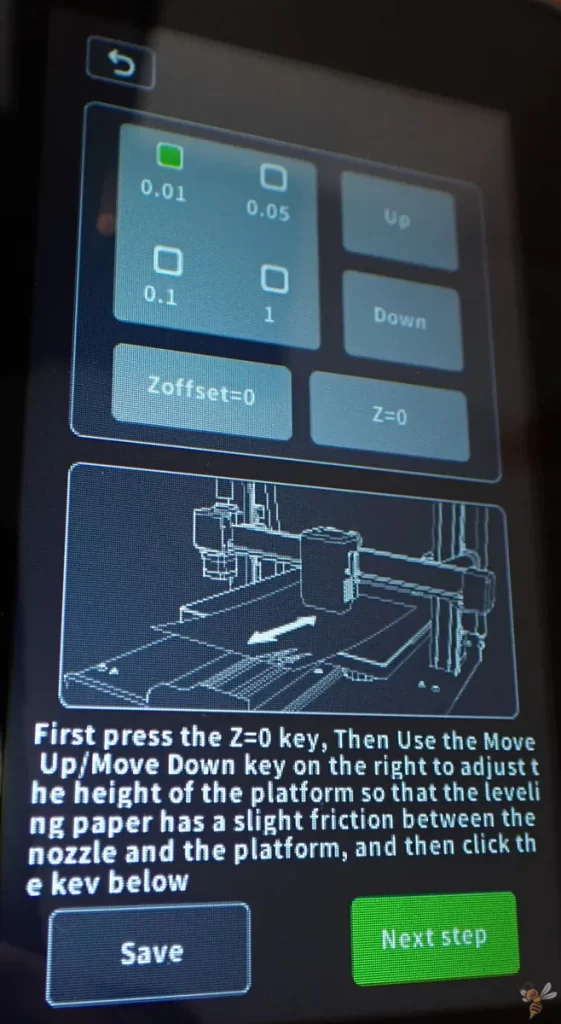

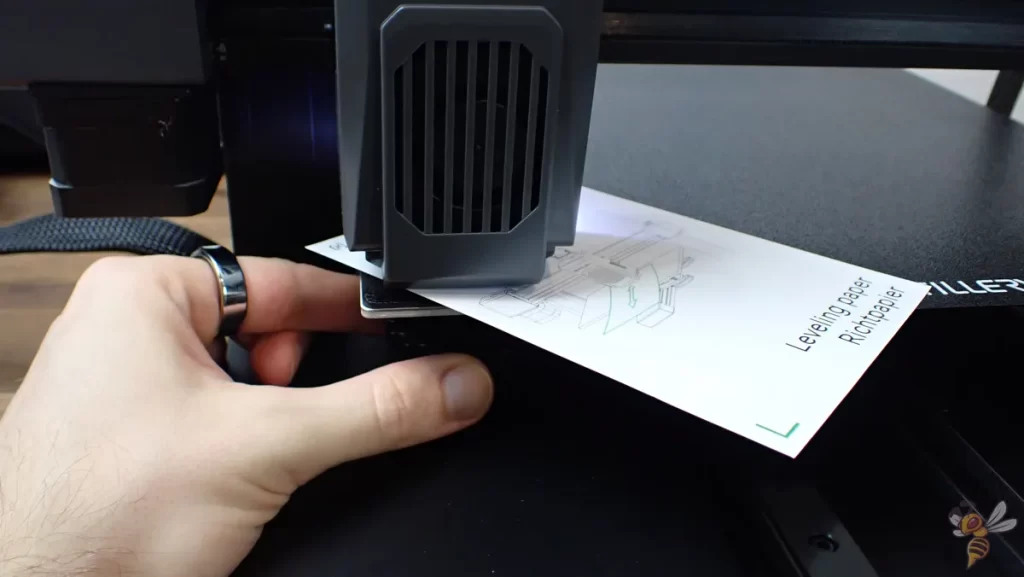

Leveling the print bed begins with a manual step in which the print bed is roughly adjusted using a piece of paper and several adjusting screws under the bed. This process is supported via the printer’s menu. After this manual adjustment, fine-tuning is carried out by the printer’s automatic leveling function.

Although some modern 3D printers dispense with manual leveling altogether, this combination of manual and automatic leveling is still common on large 3D printers such as the Sidewinder X4 Plus. This ensures that the print bed is precisely aligned, which is crucial for an even first layer and therefore for the overall quality of the prints.

Print Speed

The Artillery Sidewinder X4 Plus can achieve impressive print speeds of up to 300 mm/s, with the ability to print up to 500 mm/s in optimal conditions. However, such speeds are not achievable without careful calibration of the printer and the printing process.

The ability to print at high speeds depends heavily on the precision of the mechanical components and the efficiency of the control software. The key to these speeds on the X4 Plus is the use of linear rails on the X and Y axes, which enable stable and precise movement of the print heads. This mechanical foundation reduces vibrations and improves the overall accuracy of the print, even at higher speeds.

Another important feature that enables high printing speeds is input shaping (more on this in the next chapter). Together with a powerful extruder that ensures a consistent filament feed, the X4 Plus allows fast printing without significant loss of print quality.

The combination of these features enables the printer to overcome the physical limitations of conventional models and deliver precise results.

The high printing speed of the X4 Plus has considerable advantages, especially for large print projects. Whereas previously such projects often took several days to complete, they can now potentially be completed in just one day. This represents a significant time saving and allows users to create prototypes or produce final products more quickly.

However, it is important to note that these high print speeds are now standard on many modern 3D printers and can therefore no longer be considered a technological novelty, but rather a must-have.

Input Shaping

Input shaping is a modern method of improving print quality in the world of 3D printing, especially at high speeds. This technology addresses a key problem: the vibrations and resonances that occur when the print head moves quickly. Such movements can lead to undesirable effects in the printed object, such as ringing or ghosting, which affects the surface quality.

These vibrations can be effectively reduced by making specific adjustments to the control signal of the motor based on the analysis of the mechanical resonances of the printer. This is achieved by generating counter-rotating movements that neutralize the original vibrations.

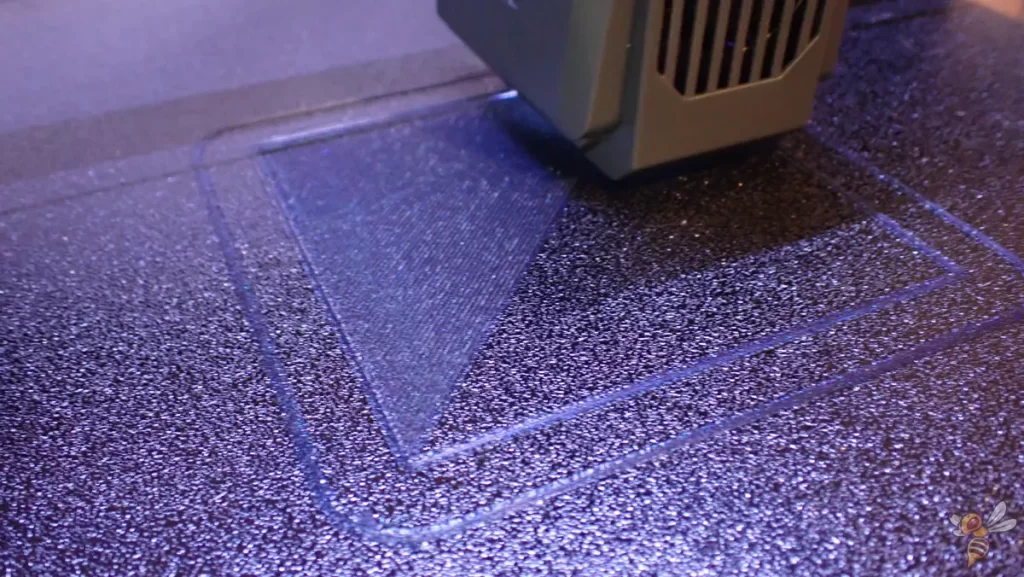

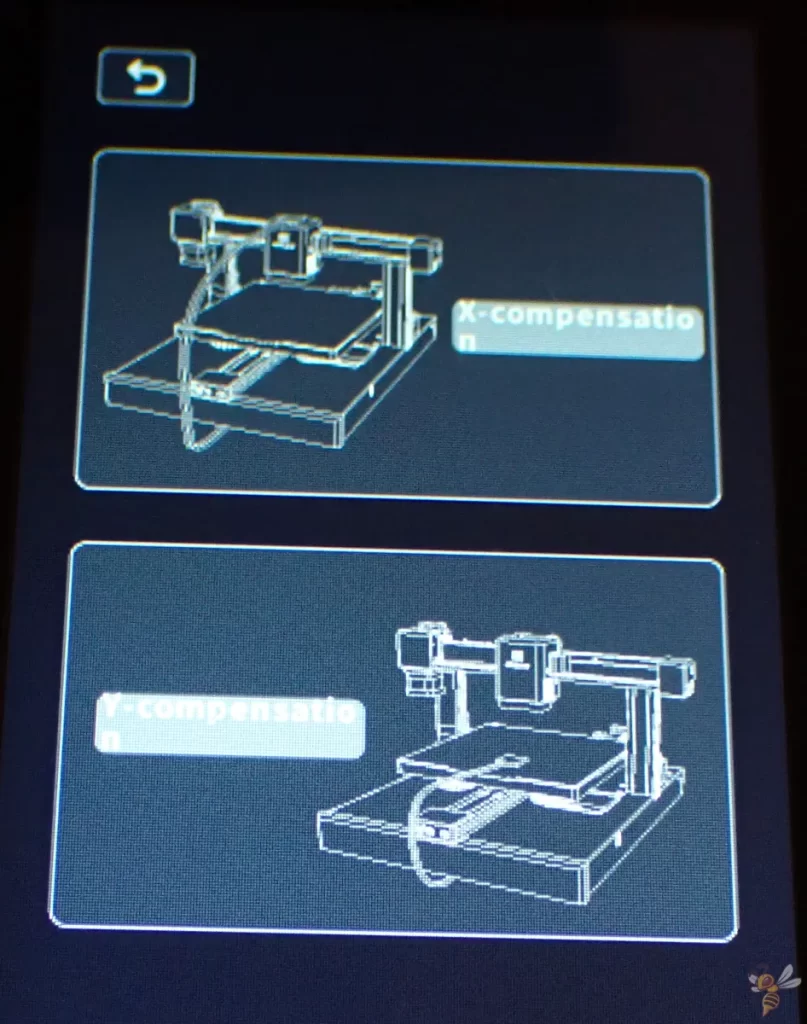

In the Artillery Sidewinder X4 Plus, this process is referred to as “resonance compensation” in the menu. The printer uses specially generated vibrations in the print head to identify the resonances of the system and adjust the movements accordingly.

This makes it possible to maintain excellent print quality even at higher print speeds without compromising on detail or surface finish.

The ability to achieve high print speeds without sacrificing quality makes input shaping an essential feature for modern 3D printers. It represents a significant advance that not only increases the efficiency of 3D printing, but also expands the applications and accessibility of this technology.

Print Volume & Stability

The Artillery Sidewinder X4 Plus is characterized by its impressive print volume of 300 × 300 × 400 mm, making it ideal for printing large objects in one piece. This capacity opens up new possibilities for projects ranging from large format artwork to functional pieces that do not require assembled pieces.

Another important aspect of the X4 Plus is its stability. By integrating cross braces on the frame, the structure of the printer is reinforced over its entire height. This design decision minimizes vibrations and significantly improves print quality, especially for tall objects.

The combination of large print volume and increased stability ensures that the X4 Plus is a reliable choice for demanding printing tasks where precision and size are equally important.

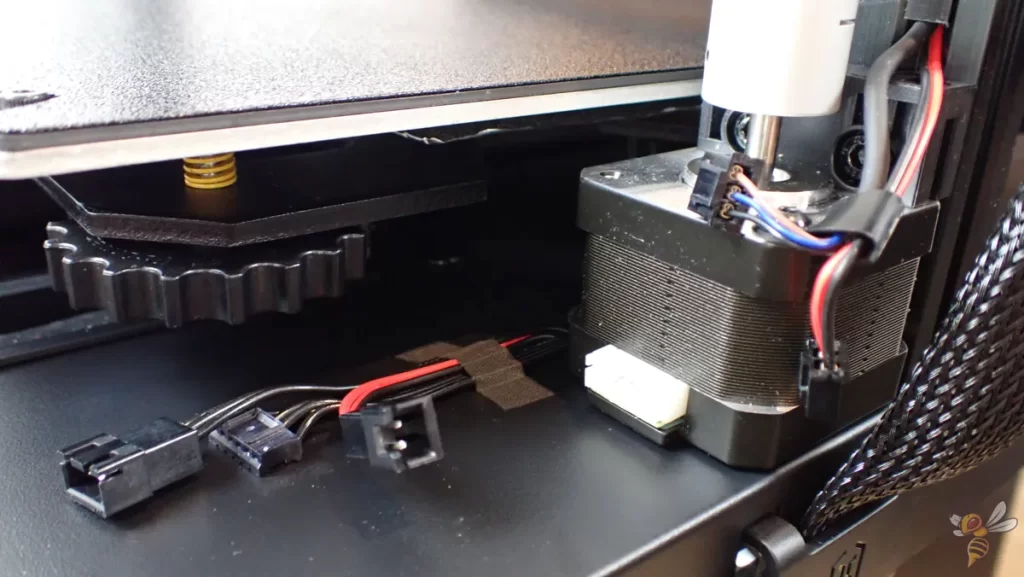

Extruder

The Artillery Sidewinder X4 Plus is equipped with a high-performance extruder that can reach a maximum printing temperature of up to 300°C.

This high temperature capacity extends compatibility with a wide range of filaments, including more demanding materials such as nylon, ABS, or reinforced filaments.

The printer uses a direct drive extruder with dual gear technology, a feature that provides more precise filament guidance and improved extrusion consistency.

Surprisingly, the extruder cannot be manually decoupled; filament changes and loading are controlled exclusively via the menu, which makes for seamless and user-friendly handling in practice, even if it may seem unfamiliar at first.

WiFi Antenna

The Artillery Sidewinder X4 Plus has an integrated WiFi antenna. Setting up the WiFi connection is straightforward and allows print jobs to be sent wirelessly and progress to be tracked remotely.

This function is particularly useful in environments where several printers are networked or if the printer is not located directly at the workstation.

I only tested the connection briefly once and otherwise transported the data between my PC and the 3D printer using the classic USB stick method.

Pressure Advance

By using Klipper as firmware, not only the “Input Shaping” feature is possible but also “Pressure Advance”, which makes extrusion much more precise.

Pressure Advance is a feature on 3D printers that optimizes the extrusion of filament to achieve a more consistent print quality, especially at high speeds and corners. It regulates how much filament is prematurely extruded before the print head changes its movement.

The aim is to reduce problems such as blobs and stringing and to print sharper corners by precisely matching the amount of extruded material to the speed of movement of the print head.

Linear Rails on X and Y Axes

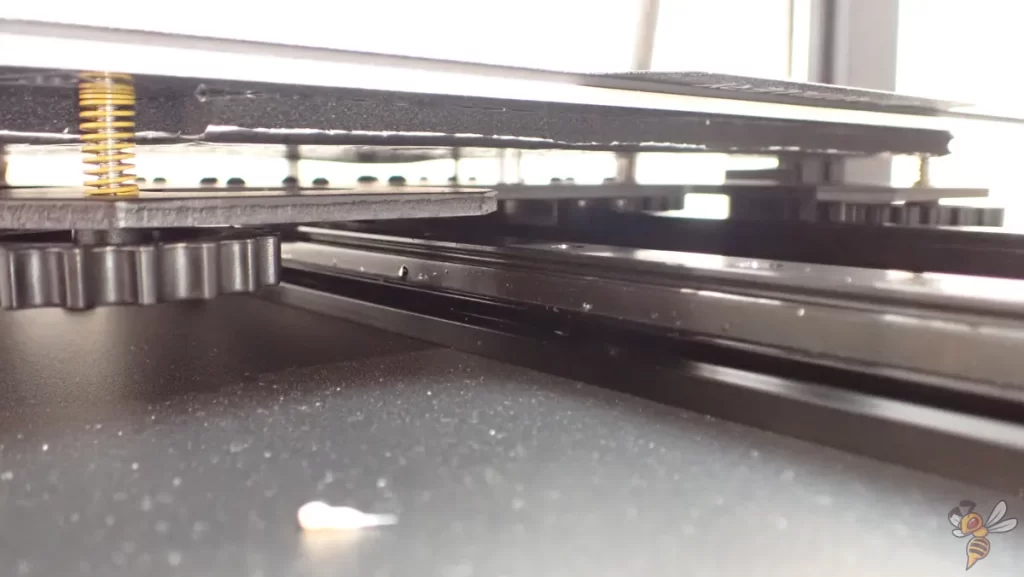

What struck me immediately on unpacking and made a very positive impression were the built-in linear rails on the X and Y axes of the Sidewinder X4 Plus.

Linear rails in 3D printers are high-precision guide rails that are used to move the print head or print bed mechanics. Unlike traditional threaded rods or belt drives, linear rails provide smoother, more stable and more accurate movement. This results in improved print quality, especially at higher speeds, as vibration and backlash are minimized.

Linear rails help the printer glide precisely across the print bed, which is critical for sharp edges and fine detail.

They require less maintenance than older systems as they are more robust and resistant to wear and tear. However, occasional cleaning and lubrication of the rails is necessary to ensure optimum performance. Therefore, some grease is included in the scope of delivery.

With their efficient and precise movement, linear rails allow the X4 Plus to reach higher speeds without compromising quality.

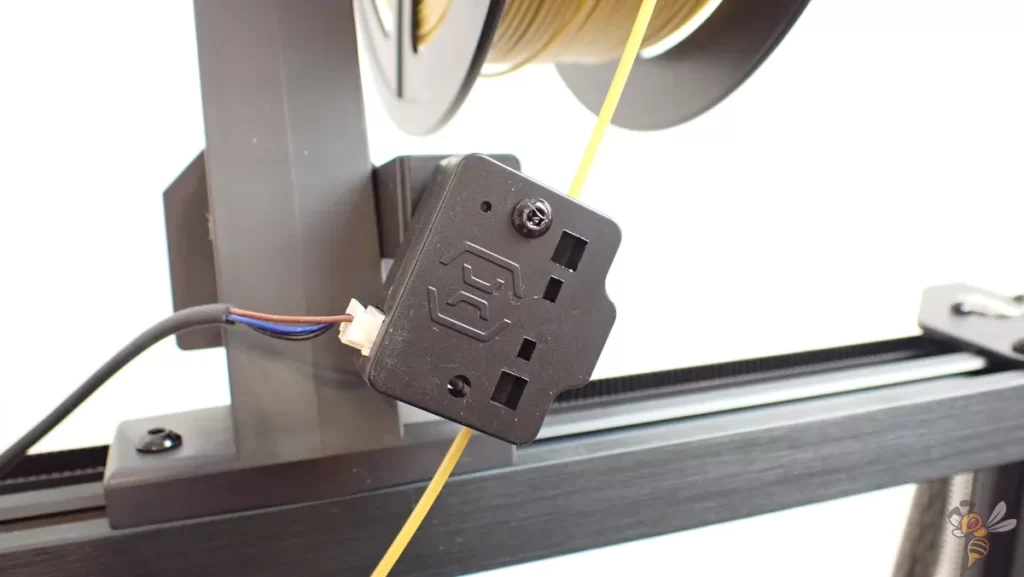

Filament Sensor

The integration of a filament sensor in the X4 Plus is also very convenient.

A filament sensor in a 3D printer is a device that monitors whether filament is present and whether it is being fed properly through the extruder. It works via optical sensors that detect when the filament either runs out or breaks off.

The main benefit to the user is the prevention of misprints when filament runs out. If a problem is detected, the printer can pause until the filament is replenished or the fault is rectified, saving time, material and energy.

Touchscreen & Menu

The 4.3-inch touchscreen of the Artillery Sidewinder X4 Plus offers an intuitive user interface that makes it easy to access all important print settings and functions.

The menu is clearly laid out so that users can quickly switch between different modes, start or pause print jobs and adjust settings such as temperature and print speed.

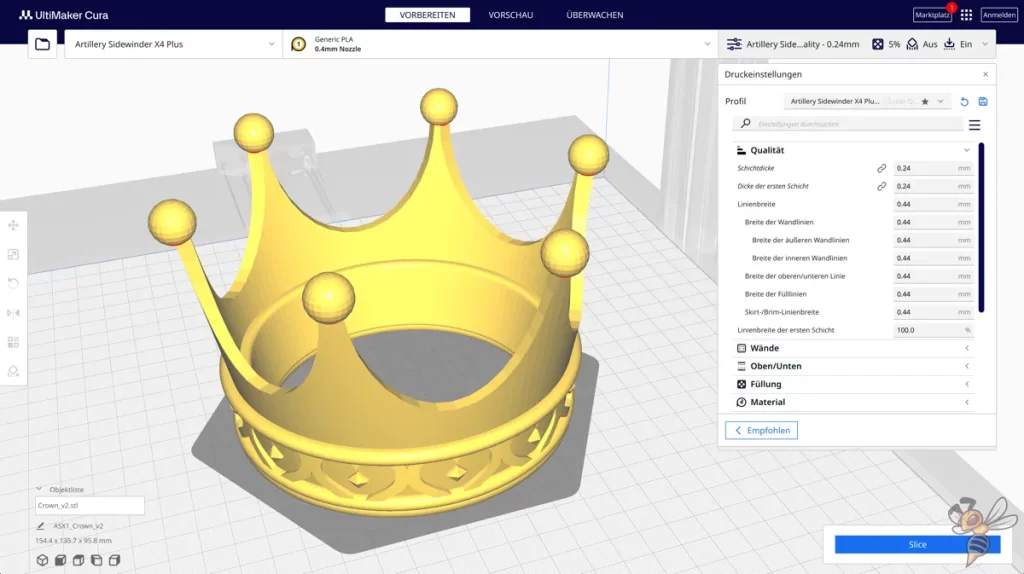

Slicer

The Sidewinder X4 Plus is operated with the Artillery Slicer as standard. However, as this slicer is not available in the latest version for iOS devices, I have created my own profile for it in Cura.

I use Cura for almost all the FDM 3D printers I test, as it is the most popular slicer for these 3D printers and also has a lot of features with which you can achieve perfect printing results.

The problem is that there is no prefabricated standard profile for the X4 Plus. I therefore had to take a blank profile and adapt it to the 3D printer. This is not recommended for most beginners in 3D printing, as there are a lot of things you have to pay attention to.

I share my Cura settings and profile here: Artillery Sidewinder X4 Plus – Cura Settings & Profile

Print Quality

The Artillery Sidewinder X4 Plus doesn’t really stand out from other models on the market for its print quality – not until you consider the speeds at which they were created!

Thanks to innovative technologies such as Input Shaping, impressive precision is achieved even at high print speeds. This means that problems such as ringing or ghosting, which often occur during fast printing processes, are effectively minimized. In addition, the positive influence of the Pressure Advance function on print quality can be clearly seen, resulting in optimized extrusion and retraction of the filament.

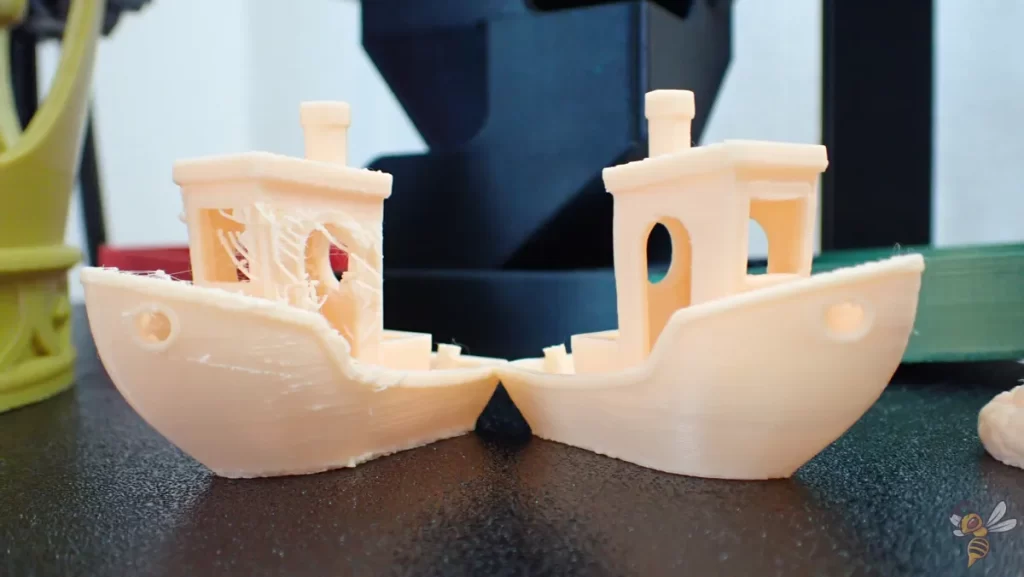

In order to fully evaluate the capabilities of the X4 Plus, I printed various challenging objects under uniform conditions. A layer height of 0.24 mm and a speed of 300 mm/s were chosen to test both the level of detail and the efficiency of the printer.

The first test prints, taken directly from the pre-sliced objects on the supplied USB stick, were almost perfect.

The first print test with my own Cura profile and the 3DBenchy object initially showed considerable quality defects. This was to be expected without calibration.

However, a series of adjustments to the print profile showed a dramatic improvement: reprinting the 3DBenchy led to an almost perfect result. This underlines the importance of careful profile tuning and the adaptability of the X4 Plus to user-specific settings.

TIP: Learn how to calibrate your 3D printer to get perfect results every time in my 3D printing course: FDM 3D Printing: The Comprehensive Course from A to Z

(The course teaches everything you need to know for FDM 3D printing in over 60 lessons. The course will get beginners up to my level in no time!)

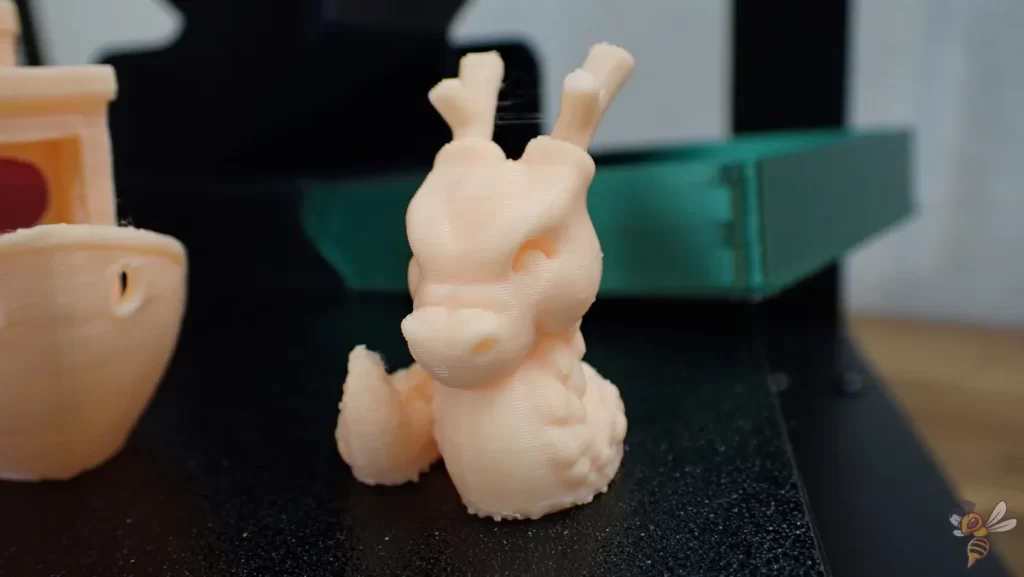

Printing a Cali Dragon as the next object revealed slight problems with stringing, which could be largely eliminated by fine-tuning the retraction settings.

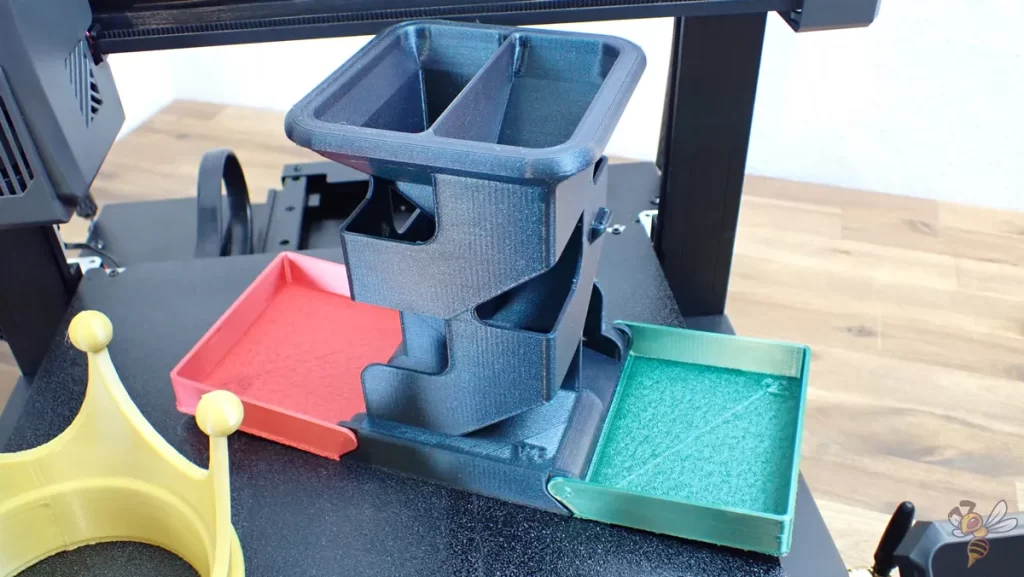

A more demanding project, a dice tower consisting of three parts, presented the printer with new challenges. Apart from the first few layers, which were too compressed – a problem that is often caused by firmware issues with new printers and can usually be fixed with a firmware update – the print quality was consistently very good.

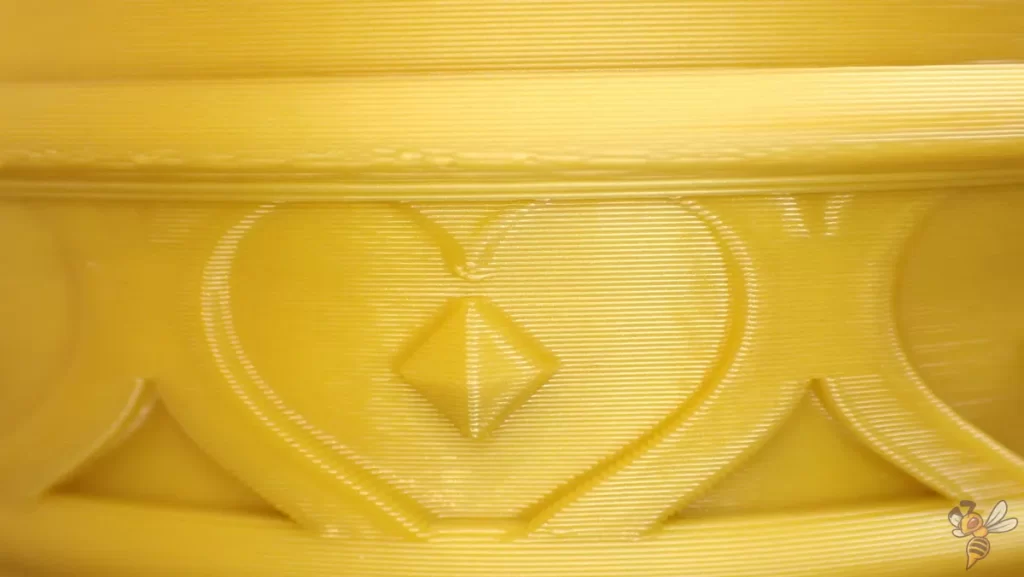

Finally, a crown with detailed elements and an interesting geometry was printed. This test once again demonstrated the outstanding print quality of the X4 Plus, in which even fine details and complex structures were reproduced almost perfectly.

This result completes the picture of the Artillery Sidewinder X4 Plus as an extremely capable 3D printer, capable of handling a wide range of printing tasks with impressive precision and reliability.

Overall, the practical results demonstrate that the Artillery Sidewinder X4 Plus not only impresses with its technological features, but also delivers consistently convincing results in practical use. The ability to process a wide range of materials and complex models with a few adjustments makes it a valuable resource for hobbyists, designers and engineers alike.

Conclusion – Is the Sidewinder X4 Plus worth it?

The Artillery Sidewinder X4 Plus impresses with its high print quality, user-friendliness and large print volume, which makes it suitable for a wide range of projects. Particularly noteworthy are the technical refinements, such as input shaping and automatic print bed leveling, which significantly improve precision and the user experience.

Despite a lack of truly ground-breaking innovations, the Sidewinder X4 Plus impresses with its solid performance and reliability, making it an attractive choice for users of all experience levels.

1 comentário

I like Artillery